Reimagining Engineering

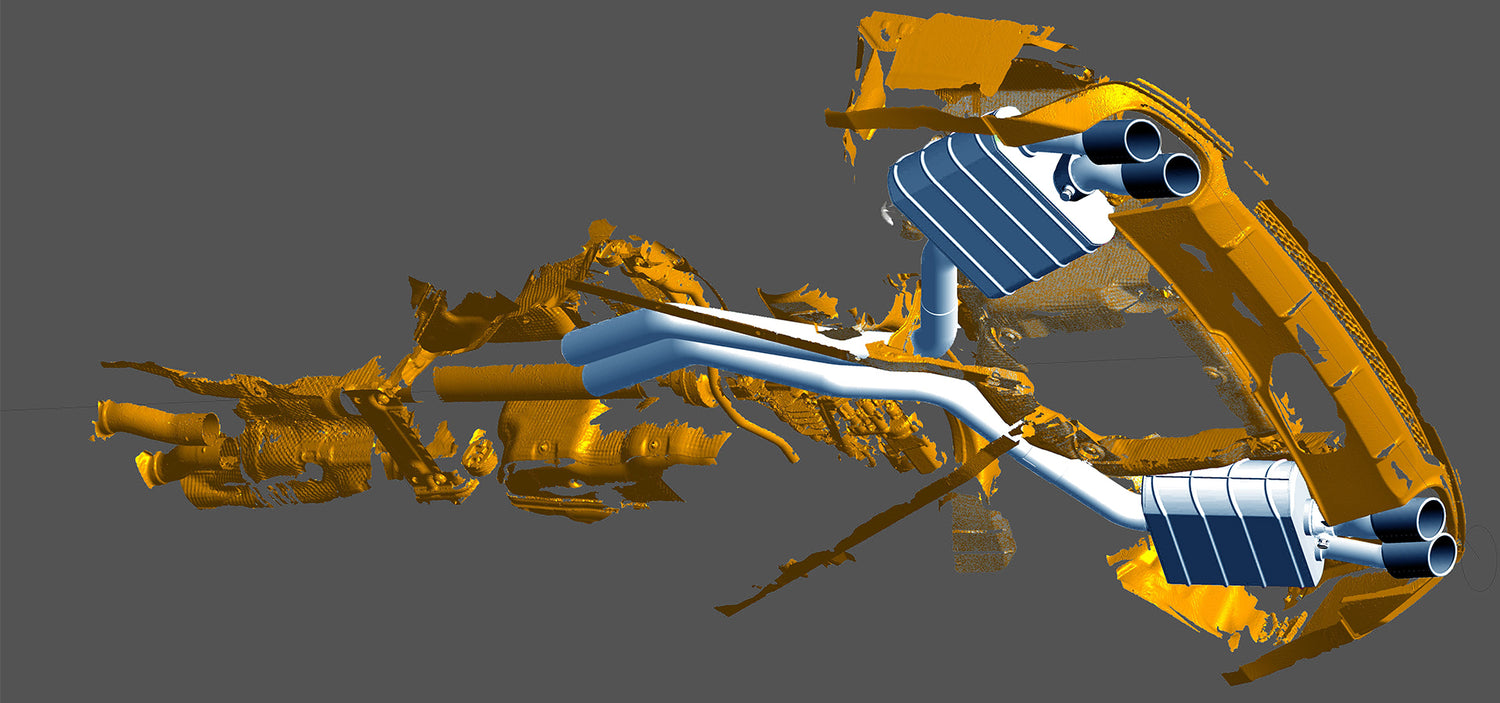

Every Capristo exhaust and carbon fiber component begins with a full 3D scan of the vehicle using our state-of-the-art laser scanning technology. This multi-dimensional rendering ensures that every product we create offers perfect OEM-level fitment. The 3D model serves as the foundation for all development work, seamlessly feeding into our CAD systems to begin the engineering process.

Once scanning is complete, the data is meticulously cleaned, refined, and processed using our proprietary CAD software. Each digital file is validated against physical measurements to guarantee dimensional accuracy. This ensures every part we manufacture not only fits flawlessly, but also performs as expected—right out of the box.

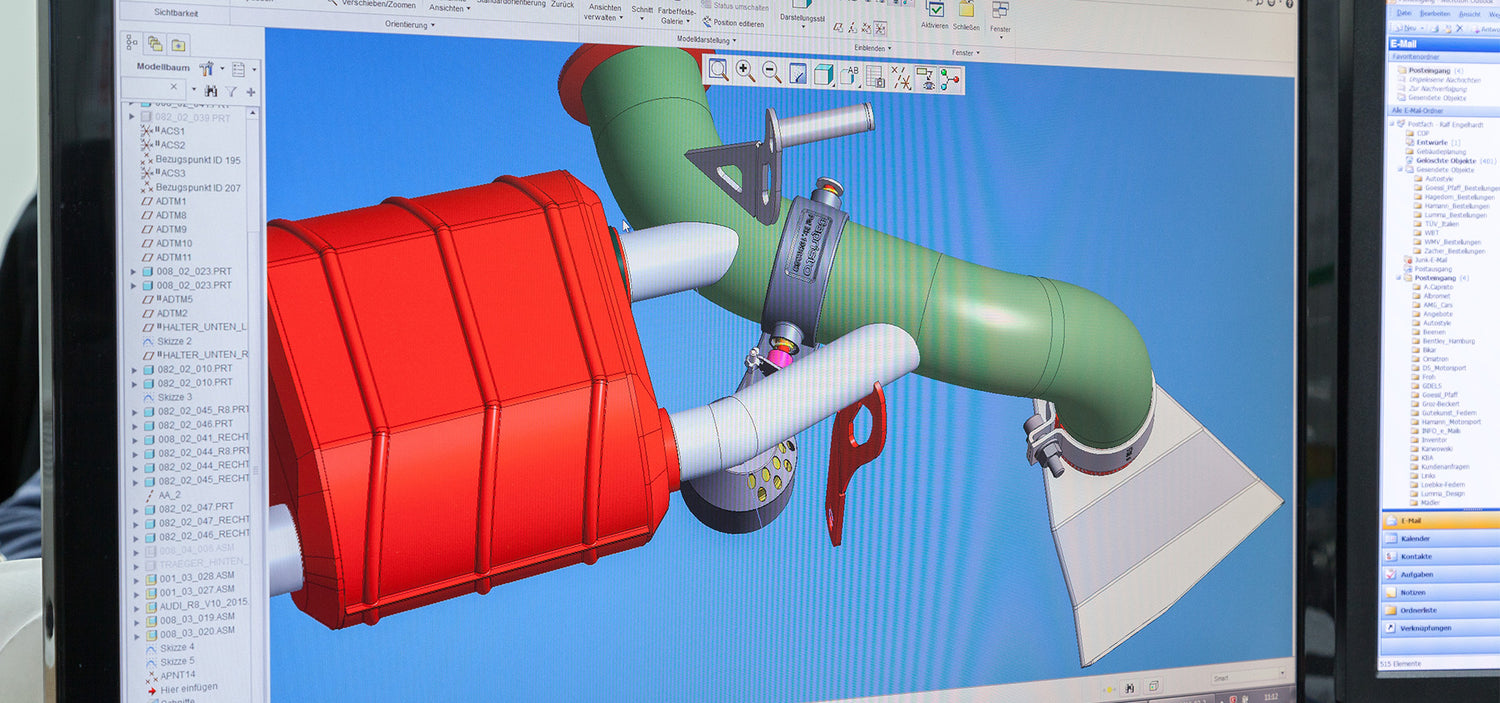

With precision measurements in place, our design team moves into the engineering phase, creating multiple prototype concepts based on the vehicle’s engine specs, sonic resonance profiles, and physical constraints. It’s here that the signature “Capristo sound” is tuned—engineered with intention and calculated resonance to give each system its distinct, performance-driven tone.

Every prototype undergoes extensive physical testing, including fitment and acoustic tuning, to achieve the perfect balance of sound, performance, and design. Only when a prototype meets our stringent standards does it move into final production.

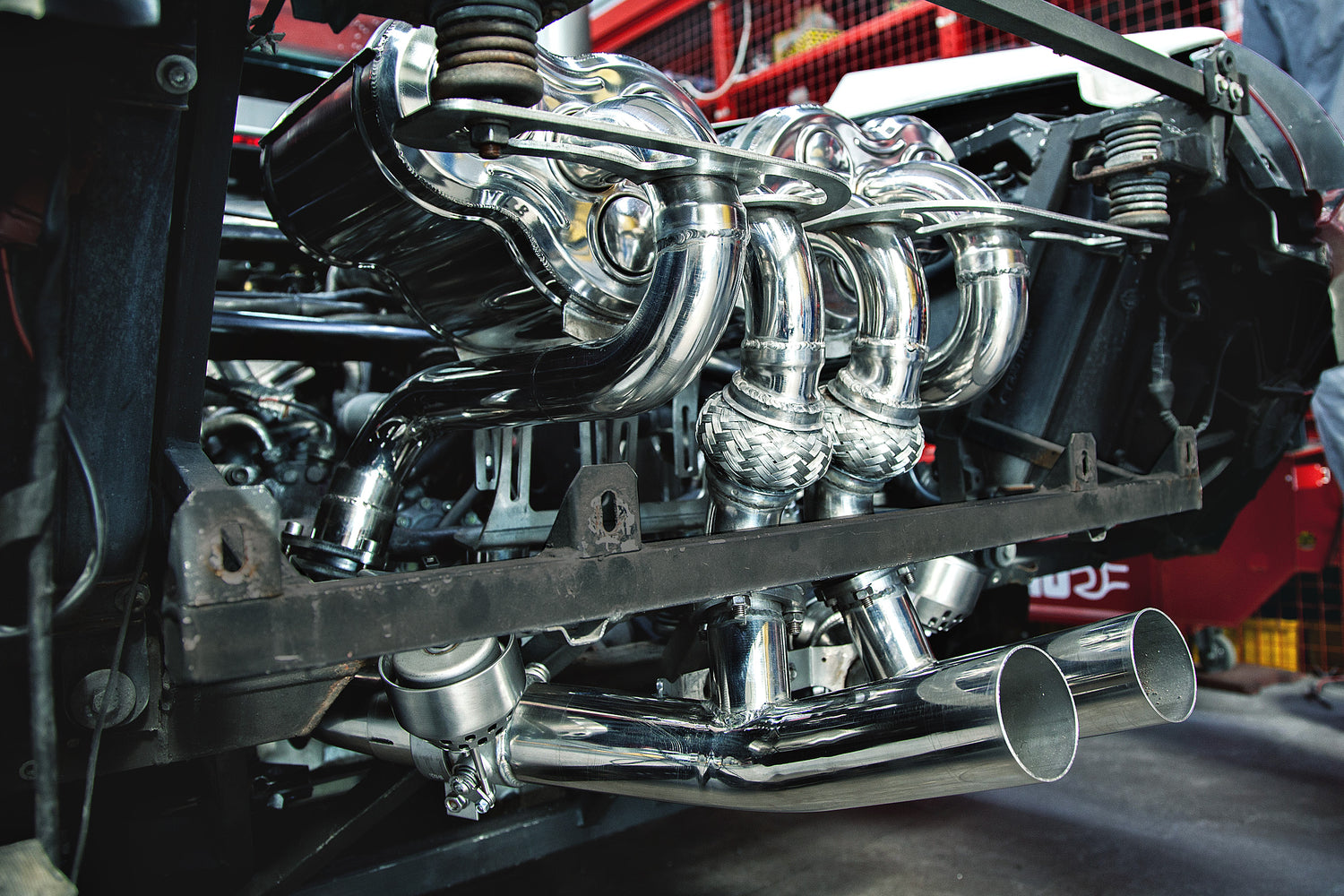

Each exhaust system is then hand-welded by a dedicated craftsman, following precise guidelines and using billet steel jigs developed in-house for consistent accuracy. Like performance engines from AMG or Ferrari, one expert is assigned to oversee the full welding process from start to finish. After CNC-bending and CNC-milling the T309 (1.4828) stainless steel, the component is expertly assembled and prepared for finishing.

Finally, every Capristo product is hand-polished to a mirror finish, resulting in an appearance that matches its performance pedigree. Engineered, tested, and built in Germany, Capristo products deliver beyond OEM-quality and unmatched aesthetic appeal.

Capristo exhaust systems are engineered without compromise, using hand-selected AISI 309 (T309) stainless steel sourced from a German foundry. T309 stainless steel was specifically chosen as it mimics similar resonance properties to Inconel, notably used in F1.

This exceptionally high-grade alloy is chosen for its superior metallurgical performance under extreme exhaust temperatures, not as a marketing preference but as a technical necessity. With significantly higher chromium and nickel content than the T304 stainless steel commonly used in automotive exhausts, T309 offers significantly greater resistance to oxidation, high-temperature corrosion, and heat-induced loss of strength.

Proven through extensive motorsport development with Lamborghini Squadra Corse and Ferrari Challenge, Capristo has demonstrated that T309 delivers nearly twice the high-temperature strength of T304 in real-world conditions. This is especially critical for mid-and-rear-engine vehicles, where exhaust temperatures can approach 1,200°F during spirited driving and exceed that in race environments. At these temperatures, T304 begins to degrade while T309 maintains its protective oxide layer and retains mechanical integrity well into the excessively elevated temperature ranges. Beyond thermal resistance, T309 exhibits higher tensile and yield strength, improved fatigue resistance, and lower elasticity under sustained heat. These characteristics allow the material to withstand repeated expansion and contraction cycles with minimal deformation, significantly reducing the risk of thermal cracking and long-term fatigue. The result is consistent performance, structural stability, and longevity under the most demanding conditions.

Quality extends beyond material selection. Capristo exhaust systems are manufactured using precision mandrel bending to ensure exact geometry and consistency throughout the system. The practice of mandrel bending improves flow efficiency by maintaining a consistent internal diameter, preventing restrictions that increase turbulence and backpressure, while also preserving uniform wall thickness for improved exhaust gas velocity and structural rigidity.

Detailed through this T309 stainless steel, Capristo's proprietary exhaust valve integration is unparalleled. With a documented 0% failure rate, Capristo offers an exhaust valve solution for every exhaust produced and every driver’s use case.

Dependent on the application, Capristo offers various exhaust valve options to ensure seamless integration and full functionality. OEM factory control maintains stock valve behavior with improved flow and the signature Capristo tone, the CES‑3 programmable controller allows customizable valve modes for various volume settings, and the E2E kit provides manual override of factory electric valves without modifying the original harness.

OEM: On vehicles equipped with factory vacuum and/or electronic valves, Capristo has developed these exhausts to utilize the vehicle’s existing valve actuators and factory ECU logic to activate the exhaust valves. Operating in accordance with the OEM ECU, the Capristo exhaust valves open and close based on RPM, throttle input, and driving mode allowing you to retain the car’s original behavior while enjoying the improved flow and sound that Capristo provides. No ancillary control module is necessary.

OEM Electronically-Controlled Valves - "E2E" Module: For vehicles equipped with factory electronic exhaust valves, our E2E electronic-to-electronic kit provides a reliable way to manually control the valves. By intercepting the OEM electronic signals with a piggy-back controller connecting between the car's OEM wiring harness and the electric valve actuators, the E2E allows you to hold the valves open with the option to restore OEM behavior. While it doesn’t offer programmable thresholds like the CES‑3, it gives you a straightforward and dependable way to achieve maximum sound and performance on demand.

OEM Vacuum-Controlled Valves - "Standard Remote" Module: For vehicles equipped with factory vacuum exhaust valves, our standard remote kit provides a reliable way to manually control the valves and force them open at the touch of a Capristo button. By intercepting the signals with a piggy-back controller connecting between the car's OEM wiring harness and the valve actuators, the remote kit allows you to hold the valves open regardless of RPM or load while preserving all factory safety settings with the option to restore OEM behavior. While it doesn’t offer programmable thresholds like the CES‑3, it gives you a straightforward and dependable way to achieve maximum sound and performance on demand.

Standalone Programmable Controller (CES‑3): On vehicles equipped without factory valves, Capristo offers the CES-3 programmable controller. This system monitors backpressure and engine conditions to offer you three selectable drive modes. With Capristo’s CES-3, you can adjust valve behavior beyond the factory logic and/or manually override it via remote, enabling a personalized driving experience for every occasion. These modes include:

Cruise: Valves open at higher exhaust pressure levels, providing a quieter and more comfortable drive.

Sport: Valves open sooner under load for a more aggressive exhaust note and increased performance.

Open: Valves remain fully open, optimized for track use or when maximum volume is demanded.

Each proprietary Capristo option balances simplicity, control, and multiple sound characteristics at the touch of a button. Accept no substitute.

3D Scanned

Every Capristo component starts with the creation of a complete 3D rendering of the vehicle utilizing our state-of-the-art 3D laser scanners. Creating this multi-dimensional image of the car is the most important baseline to ensure perfect OEM level fitment of the exhaust or carbon fiber pieces. The rendering generated serves as the starting basis for the product prototype development within our CAD computer software.

DIGITALLY PROCESSED

Once the scan is complete the data is prepared, digitally cleaned and exported for further processing using our proprietary CAD-Software. Every file is then cross checked against physical measurements to ensure accuracy.

COMPUTER ASSISTED DESIGN

The digital process starts the beginning of the prototype manufacturing. Utilizing engine specifications, sonic resonance values, and dimensional restrictions, Capristo designs multiple prototype concepts for physical evaluation. The unique “Capristo sound” the brand is known for is achieved through the constant application of this bespoke formula applied to the specific data matrices of the specific car’s attributes.

EXTENSIVELY TESTED

Once the digital design processes are finalized multiple system prototypes are produced. Each of these designs are then test-fitted and checked for performance and sound superiority. Only once the perfect balance of these two goals is found is the result achieved and ready for the next step.

HAND WELDED

Upon completion of prototyping and testing, the system is now ready for serial production and will be manufactured based on the specific precise guidelines. Billet Steel Jigs are created in-house to ensure 100% accuracy and consistency of each system that is produced. Similar to engine production at AMG or Ferrari, one welder is assigned to each production model who will then carry out the production from start to finish. After CNC-bending and CNC-milling of the base T309 (1.4828) stainless steel the exhaust is ready for welding. All Capristo Automotive products integrate this state-of-the-art technology to guarantee the highest standard of quality.

MIRROR FINISHED

After the product is completed, the system is hand-polished to a mirror finish and ready for installation on your vehicle. Only with Capristo are you ensured of 100% German, beyond OEM-level design and construction of your performance modifications. Accept no Substitute. Capristo.